Crucibles

Precision-engineered ceramic crucibles for high-temperature applications and demanding industrial processes

Advanced Ceramic Crucibles

Henson Ceramics Limited has developed a range of crucibles in a variety of materials to suit almost any application. These products, which may be slip-cast or isopressed, are available in a range of sizes from a few millilitres to several litres.

Typical uses are for high temperature calcinations (>2000°C), molten glass/metal processing, rapid thermal cycling (rotary kilns), and gemstone purification for the jewellery industry.

Whilst the majority of applications require the ceramic to be impervious, porous forms of most sizes are available on request.

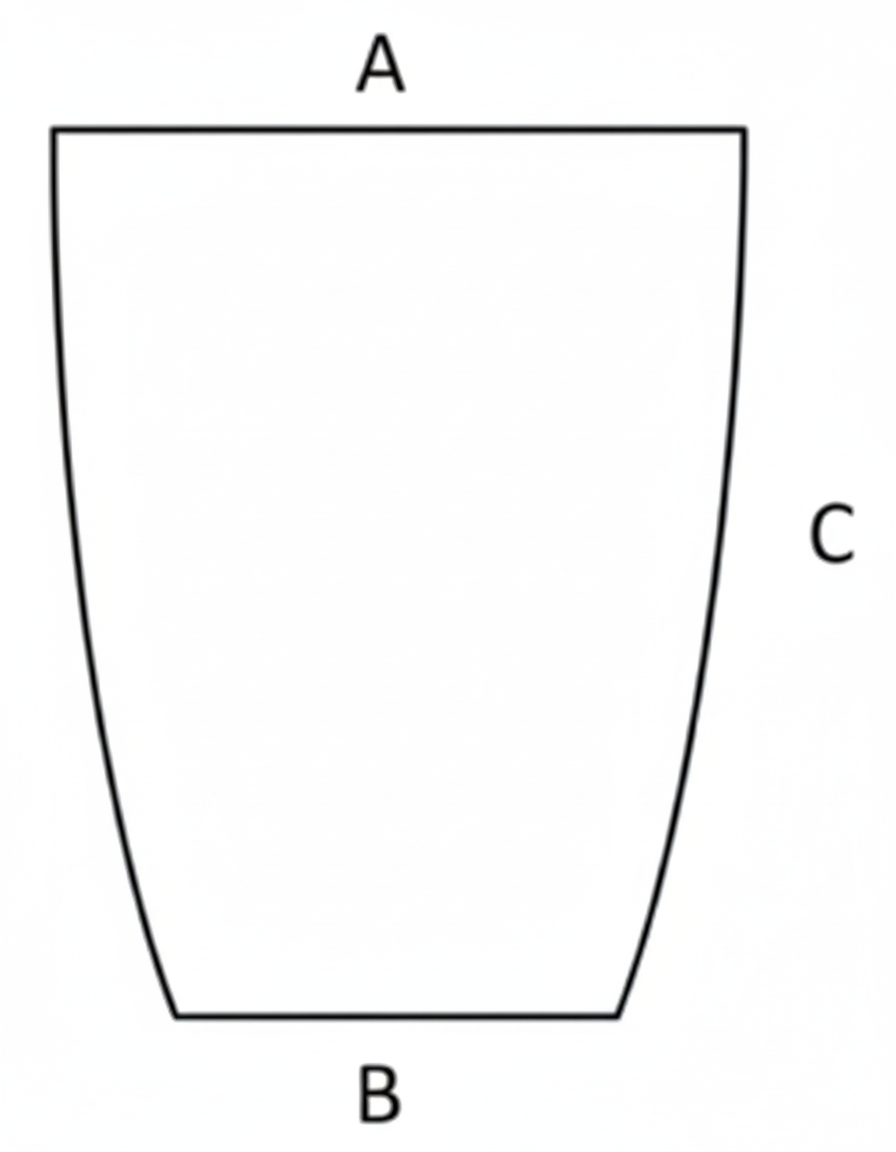

Understanding Crucible Dimensions

Dimension Reference

All crucible dimensions in our specification tables follow this standard measurement system:

- ATop Diameter (Ø)

Internal diameter at the top opening

- BBottom Diameter (Ø)

Internal diameter at the base

- CHeight

Overall internal height of the crucible

Standard crucible cross-section showing measurement points

Technical Specifications

Temperature Range

Operating temperatures up to:

- Alumina: 1800°C

- Zirconia: 2200°C

- Magnesia: 2000°C

Material Options

Available ceramic compositions:

- Alumina

- Magnesia

- Zirconia (3YSZ, 5YSZ, 8YSZ)

- Others available on request

Size Range

Custom and standard sizes:

- Capacity: 15ml to 3000ml

- Wall thickness: 1mm - 5mm

- Various shapes and forms

Standard Sizes Available

T-Series (Tall Form)

| Type | Volume (ml) | Top Ø (mm) | Bottom Ø (mm) | Height (mm) |

|---|---|---|---|---|

| T150 | 150 | 60 | 30 | 85 |

| T250 | 250 | 69 | 40 | 93 |

| T300 | 300 | 80 | 44 | 100 |

| T450 | 450 | 85 | 52 | 110 |

| T500 | 500 | 90 | 55 | 120 |

| T750 | 750 | 110 | 57 | 135 |

| T1000 | 1000 | 115 | 65 | 155 |

| T2000 | 2000 | 145 | 83 | 193 |

| T3000 | 3000 | 168 | 96 | 224 |

S-Series (Short Form)

| Type | Volume (ml) | Top Ø (mm) | Bottom Ø (mm) | Height (mm) |

|---|---|---|---|---|

| S015 | 15 | 35 | 18 | 32 |

| S025 | 25 | 40 | 21 | 36 |

| S050 | 50 | 50 | 25 | 45 |

| S100 | 100 | 60 | 30 | 50 |

| S140 | 140 | 70 | 40 | 60 |

| S300 | 300 | 85 | 40 | 83 |

| S500 | 500 | 97 | 52 | 102 |

Custom dimensions and specifications available upon request. Contact us for pricing and availability.

Applications

Metal Melting

Precious metals, alloys, and high-temperature metal processing

Materials Testing

Thermal analysis, ash testing, and material characterization

Glass Production

Glass melting and frit production in controlled environments

Chemical Analysis

Sample preparation and high-temperature chemical reactions

Research & Development

Laboratory-scale material synthesis and testing

Quality Control

Loss on ignition testing and material purity analysis

Powder Processing

Calcination and sintering of ceramic and metal powders

Foundry Operations

Industrial metal casting and alloy development

Gemstone Purification

High-temperature treatment for the jewellery industry

Rotary Kilns

Rapid thermal cycling applications

Why Choose Our Crucibles

Exceptional Purity

High-purity materials minimize contamination and ensure accurate results

Thermal Shock Resistance

Engineered to withstand rapid temperature changes without cracking

Chemical Inertness

Resistant to acids, bases, and molten metals for reliable performance

Precision Manufacturing

Consistent wall thickness and dimensional accuracy for reproducible results

Long Service Life

Durable construction provides extended operational lifetime

Custom Solutions

Bespoke designs available to meet specific application requirements

Ready to Discuss Your Requirements?

Contact our technical team to discuss your specific crucible needs and receive expert guidance