Glass Ceramics

Advanced glass-ceramic materials combining the best properties of glass and crystalline ceramics

Engineered Glass-Ceramic Solutions

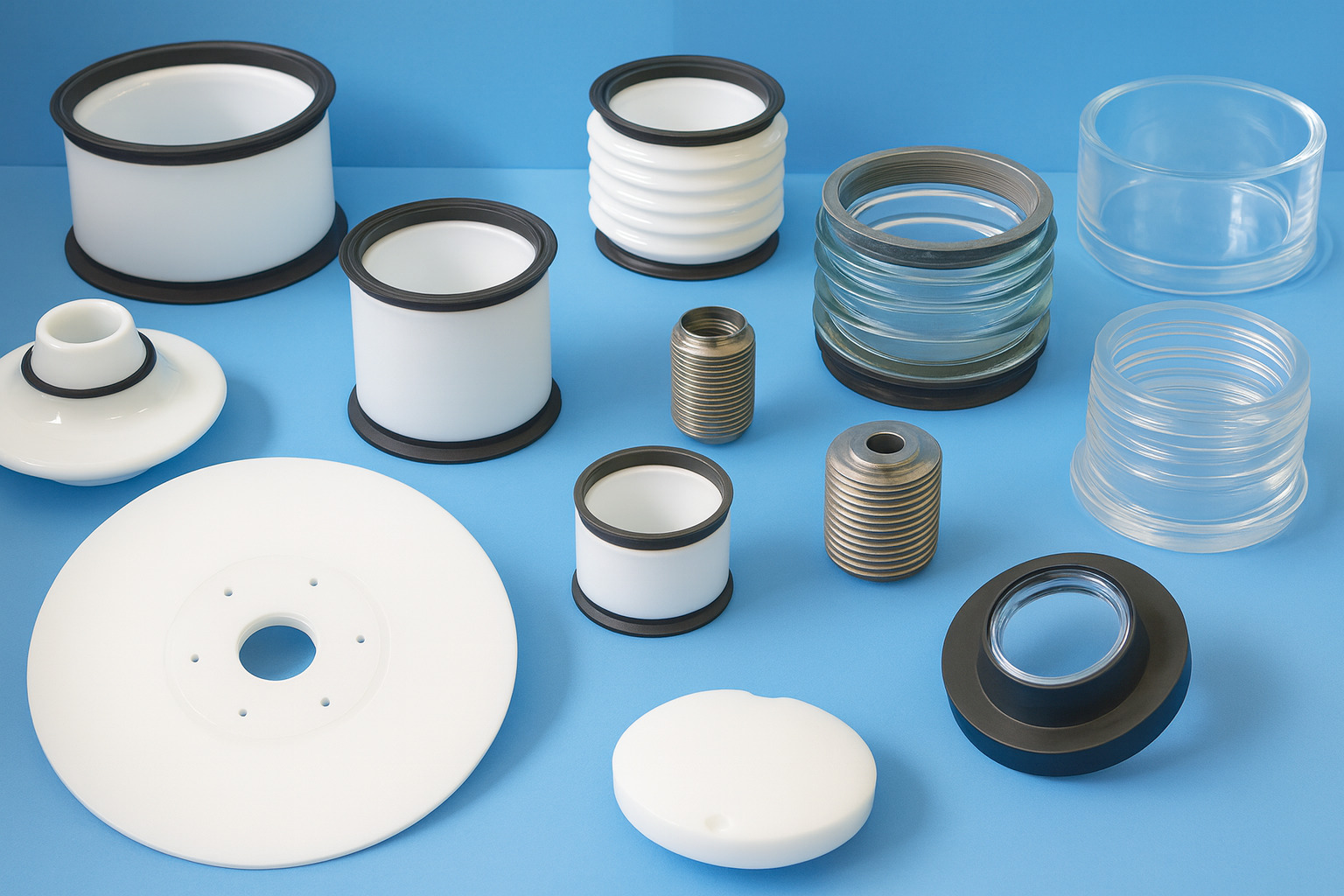

Glass ceramic materials are finding increasing application in industry because of their unique properties, particularly their ability to be tailored to match the physical properties of other materials and form glass to metal bonds. Through controlled crystallization, we transform glass into polycrystalline materials with exceptional performance characteristics.

Henson Ceramics Limited currently manufactures glass-ceramic/metal envelopes for high vacuum switches, as well as a variety of glass ceramic discs and pressed glass components. Other glass-ceramic materials which have recently gone into production are infra-red transmitting substrates, matched expansion coating materials and a glass ceramic with "zero" expansion.

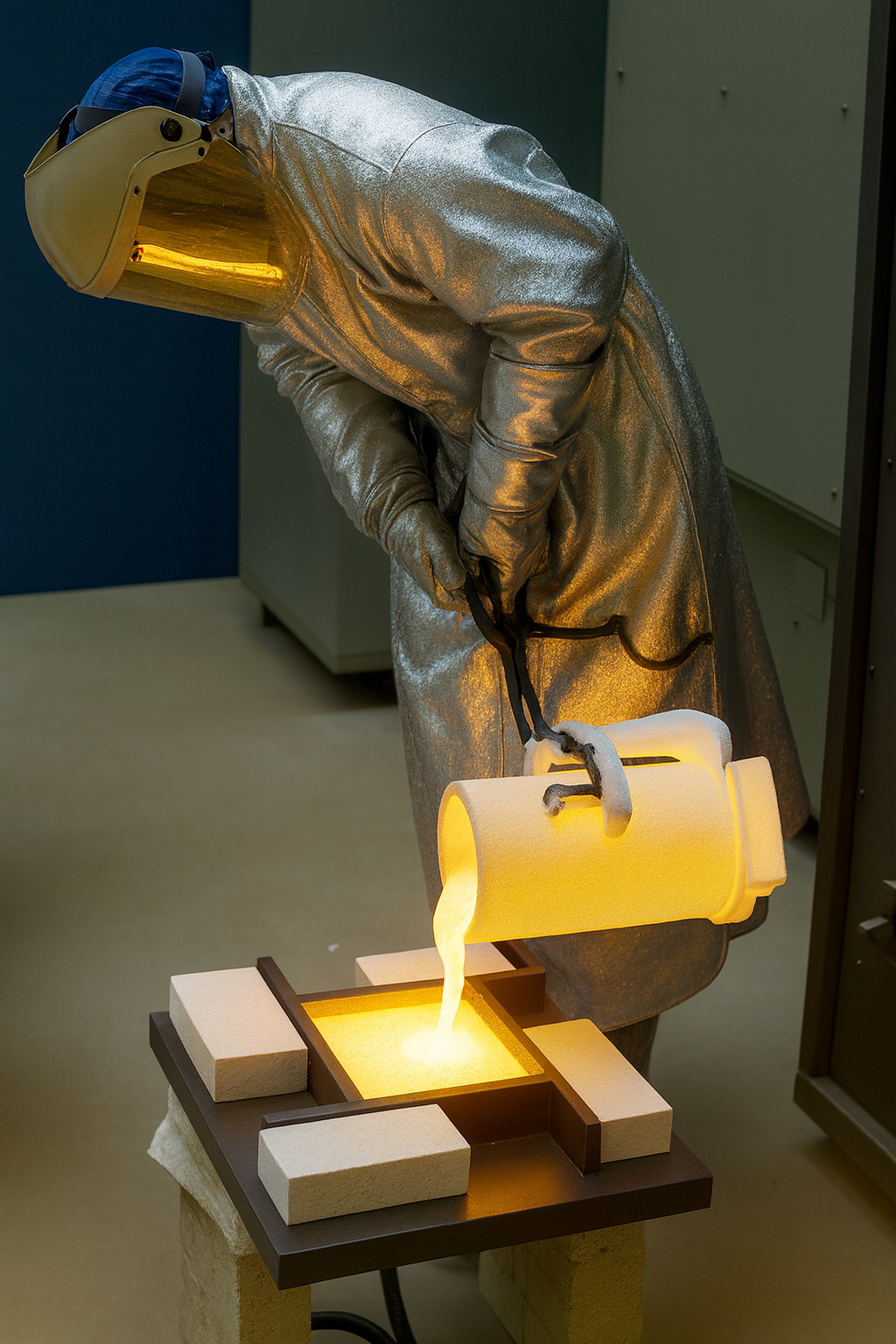

Facilities are available to manufacture and shape glass materials by casting, centrifugal casting, pressing, drawing and blowing. The amorphous material is then heat treated which transforms the glass into glass ceramic, imparting properties of high strength and chemical durability.

Technical Specifications

Thermal Properties

Exceptional thermal performance:

- Near-zero thermal expansion

- Temperature resistance to 800°C+

- Excellent thermal shock resistance

Mechanical Strength

Superior mechanical properties:

- High flexural strength

- Excellent hardness and wear resistance

- Low porosity and high density

Material Systems

HCL 2000 Series compositions:

- HCL 2087 - Matched to 17% Cr/Fe

- HCL 2088 - Matched to molybdenum

- HCL 2089 - Cordierite glass ceramic

- HCL 2090 - Zero expansion coefficient

- HCL 2091 - Matched to copper

Technical Glasses - HCL 5000 Series

- HCL 5010 - Calcium aluminate

- HCL 5020 - Sodium silver phosphate

Bespoke Services

In addition to standard materials, HCL offers a bespoke speciality glass service and can provide customers with frits, powders, and inks to any prescribed particle size distribution.

High-Quality Glass Production

Several high temperature furnaces have been installed to produce high purity glass-ceramic materials of optical quality, specially designed for glass ceramic seals. In addition, facilities are available to manufacture glass exhibiting high electromagnetic transmission over a wide frequency range. The high quality required for certain applications is achieved by vacuum melting and special processing.

Applications

Aerospace

Radomes, thermal protection systems, and structural components

Ballistic Armour

High-performance protective systems and defense applications

Chemical Industry

Corrosion-resistant equipment and process components

Dental

Dental restorations, implants, and biocompatible devices

Infrared Systems

IR transmitting substrates and optical components

Medical Devices

Bioceramics and diagnostic equipment components

Military

High-performance components for defense applications

Power Engineering

High vacuum switches and electrical insulation

Radiation Dosimetry

Measurement devices and analytical tools

Optical Systems

Telescope mirrors, laser components, and precision optics

Electronics

Substrates, insulators, and high-temperature packaging

Energy Systems

Solar concentrators, thermal storage, and energy conversion

Why Choose Our Glass Ceramics

Dimensional Stability

Near-zero thermal expansion ensures precise dimensions across temperature ranges

Thermal Shock Resistance

Withstands rapid temperature changes without cracking or failure

Chemical Durability

Excellent resistance to acids, bases, and environmental degradation

Optical Properties

Available in transparent, translucent, or opaque variants as required

Machinability

Can be precisely machined to tight tolerances before final crystallization

Custom Formulations

Tailored compositions to meet specific performance requirements

Explore Glass-Ceramic Solutions

Contact our materials specialists to discuss how glass ceramics can enhance your application